HVAC Apprenticeship Program

Earn While You Learn

- Have you wanted to get into the heating and cooling field, but just not sure where to start?

- Are you lacking the thousands of dollars it costs for schooling?

Look no further, because Service Legends is proud to have our very own Federal- & State-approved heating and cooling apprenticeship program. This program is designed to prepare team members with the skill sets to enjoy a rewarding career as heating and air conditioning professionals.

Our in-house apprenticeship program is not easy though; our team members are required to pass written and physical exams, and this typically requires study time outside of work hours. So if you’re driven, self-motivated, and ready to take on this challenge for a rewarding career, we encourage you to join us to be a Legend. Service Legends is more than just a residential heating and cooling company – we are a big family and all we’re missing is you!

Start Your Career Today – Apply Now

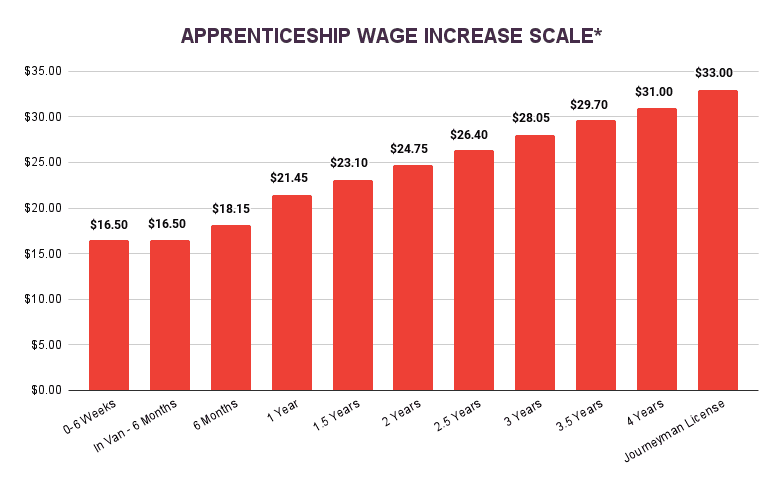

Apprenticeship Pay Scale

Wage increases will be granted upon the successful completion of both on-the-job training and related instruction. Apprentices shall be paid a progressively increasing schedule of wages based on the following schedule:

*Minimum 1,000 hours worked per 6-month period

Start Your Career Today – Apply Now

What You Can Expect

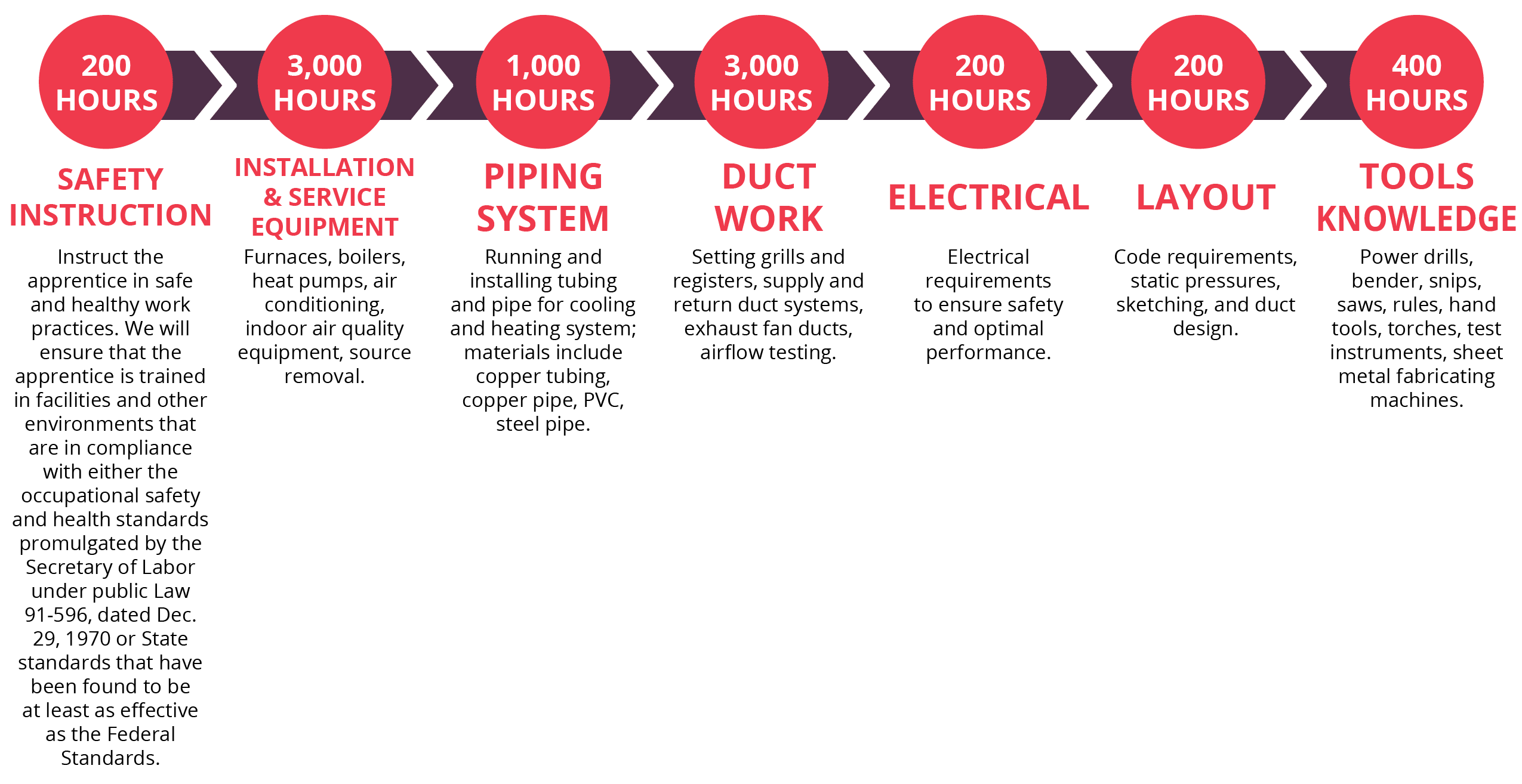

The Service Legends apprenticeship program provides the knowledge and training you need so you can perform proper HVAC services/maintenance on heating and air conditioning systems. This includes diagnosing and preventing HVAC system failures, making repairs and HVAC replacements, sheet metal skills, math skills, and everything in between. Our program will not only teach you professional communication (soft skills) for the trades, but we will guarantee that you will be comfortable and ready to use your new skill set before you’re out in the field.

Individuals that join the team for the apprenticeship program will be on a probationary period for 6 weeks. This time will be spent doing intensive studying, training, and on-the-job shadowing. Starting pay is $16.50 per hour for the first six months at Service Legends.

During the first 6 weeks new apprentices will be required to pass and obtain the following:

Start Your Career Today – Apply Now

Start Your Career Today – Apply Now

Knowledge & Skills for Life

Our 4-year apprenticeship program will equip you with the skills and knowledge to have a long-lasting and successful career in Des Moines, Iowa.